Finding the current state

I started with a deep evaluation of how the software was addressing the customers needs. I sat with customers to see where the existing tools were helping and where they were falling short.

While the software solved the immediate technical needs, I identified several major opportunities to improve the handoff between teams. This was the key to reducing that 65% planning lag.

Current Issues Addressed

Customers need to manage 2D and 3D representations of their facilities independently.

Our ability to sync between 2D and 3D representations, keeping the in-sync and automatically managing the relationship between them.

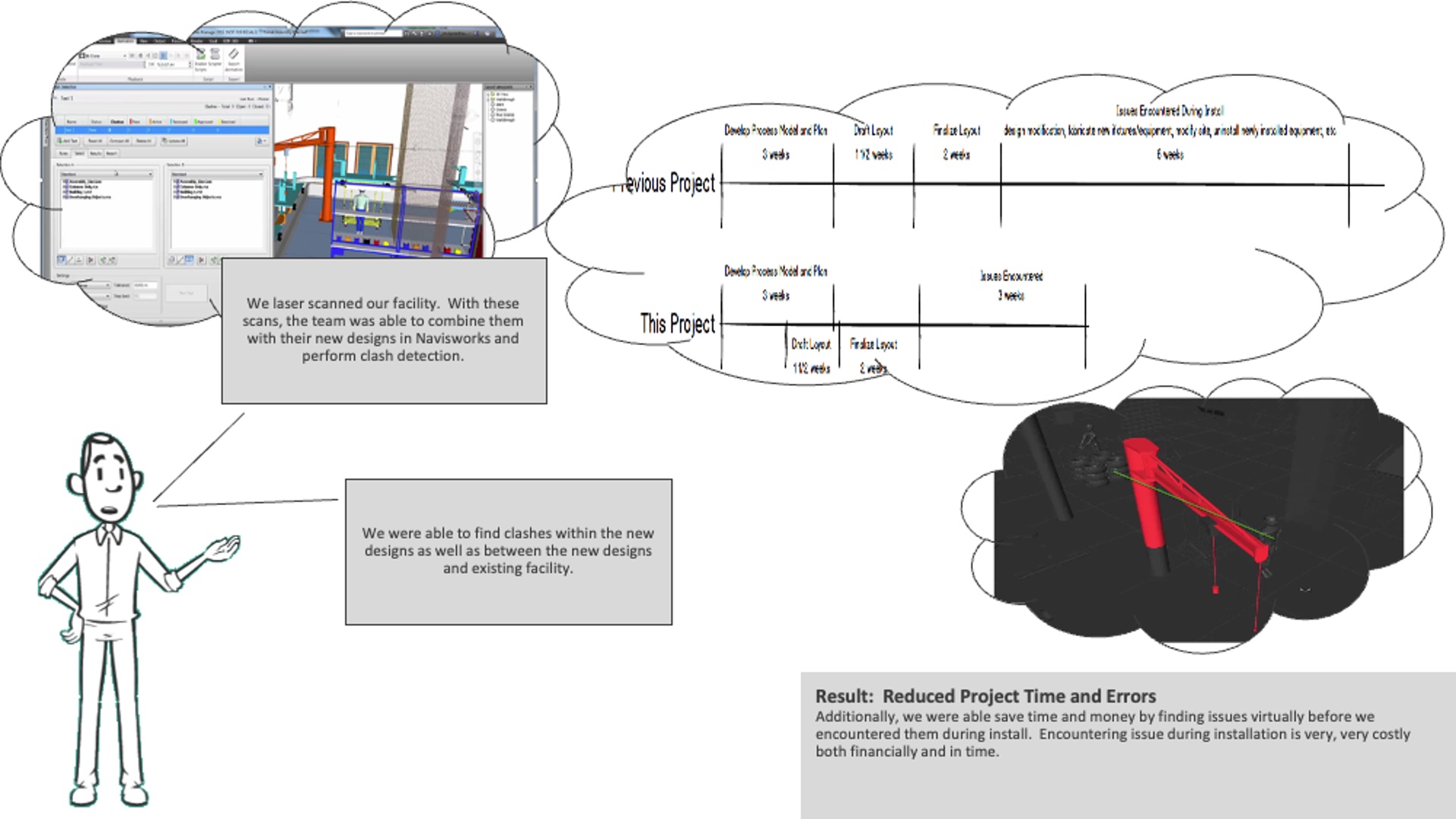

Costly space and interference issues encountered at build/install time.

Our ability to aggregate various data points and perform interference checks virtually during the design phase helps to catch these issues way before build/install and avoid costly mistakes.

Overall efficiency

All of our various layout tools and automations (such as connectors, assets, 2D-3D sync, etc.) address many issues, but likely not all.

Data management - managing all of the various pieces of data from factory layouts and assets to their release process and change order tracking.

Our integration with Vault addresses these issues (with room for improvement)

Many customers today rely on spreadsheets with formulas, completely disconnected from their layout designs to process plan.

Although not well known, Process Analysis is part of the Factory Design Utilities offering today to help them move out of spreadsheets and provides simulation and real-time analysis. (one major shortcoming today, is that the data is still disconnected from the rest of the layout design)

Identified Key Opportunities

- → Centralize technical data to prevent silos and facilitate true multi-user workflows.

- → Create a real time feedback loop for global teams.

- → Provide a true data sync with conflict resolution.

Mapping the path from A to B

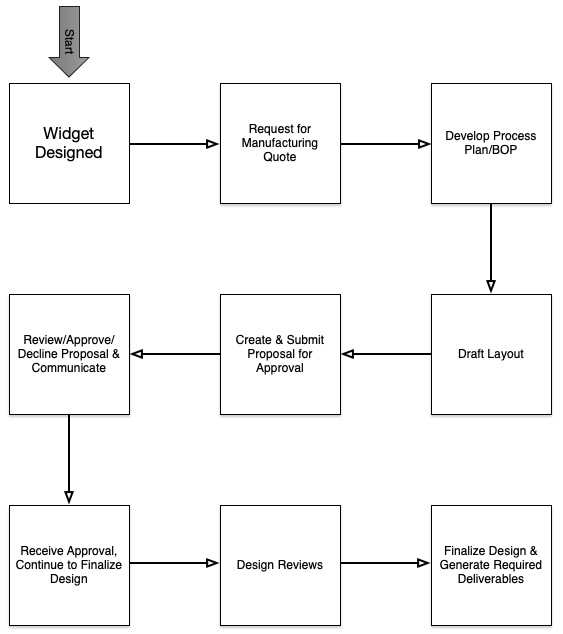

High Level User Flow

This overview allowed us to align on the broad strokes of the customers process. Click to view larger.

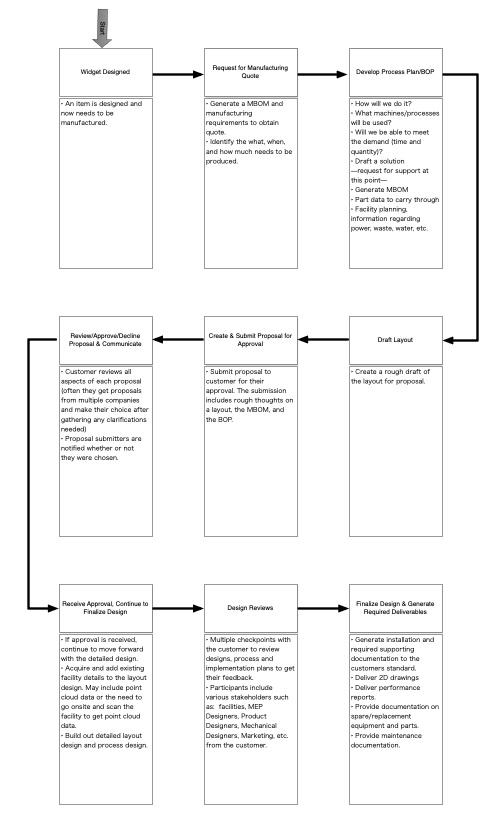

Detailed User Flow

A granular look at the process required for industrial planning. Click to view larger.

Defining the Vision

To keep focused on the "Why," we developed several Problem Statements. These became our north star during the design phase.

"In what ways might we enable collaboration and better communication?"

"In what ways might we help customer complete their projects faster, more efficiently, and with fewer errors?"

"In what ways might we allow customers to reuse their data?"

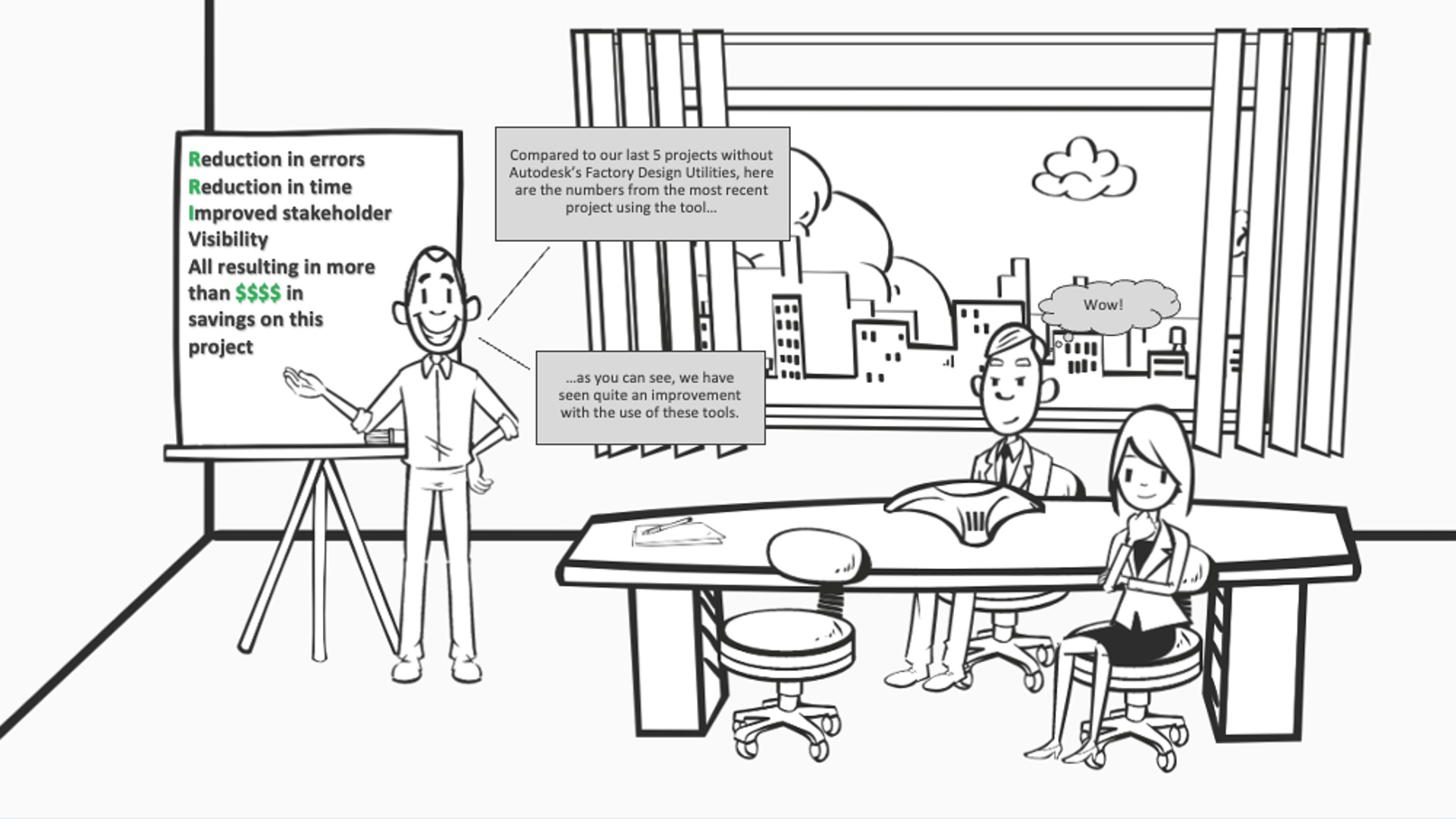

Storyboarding the Vision

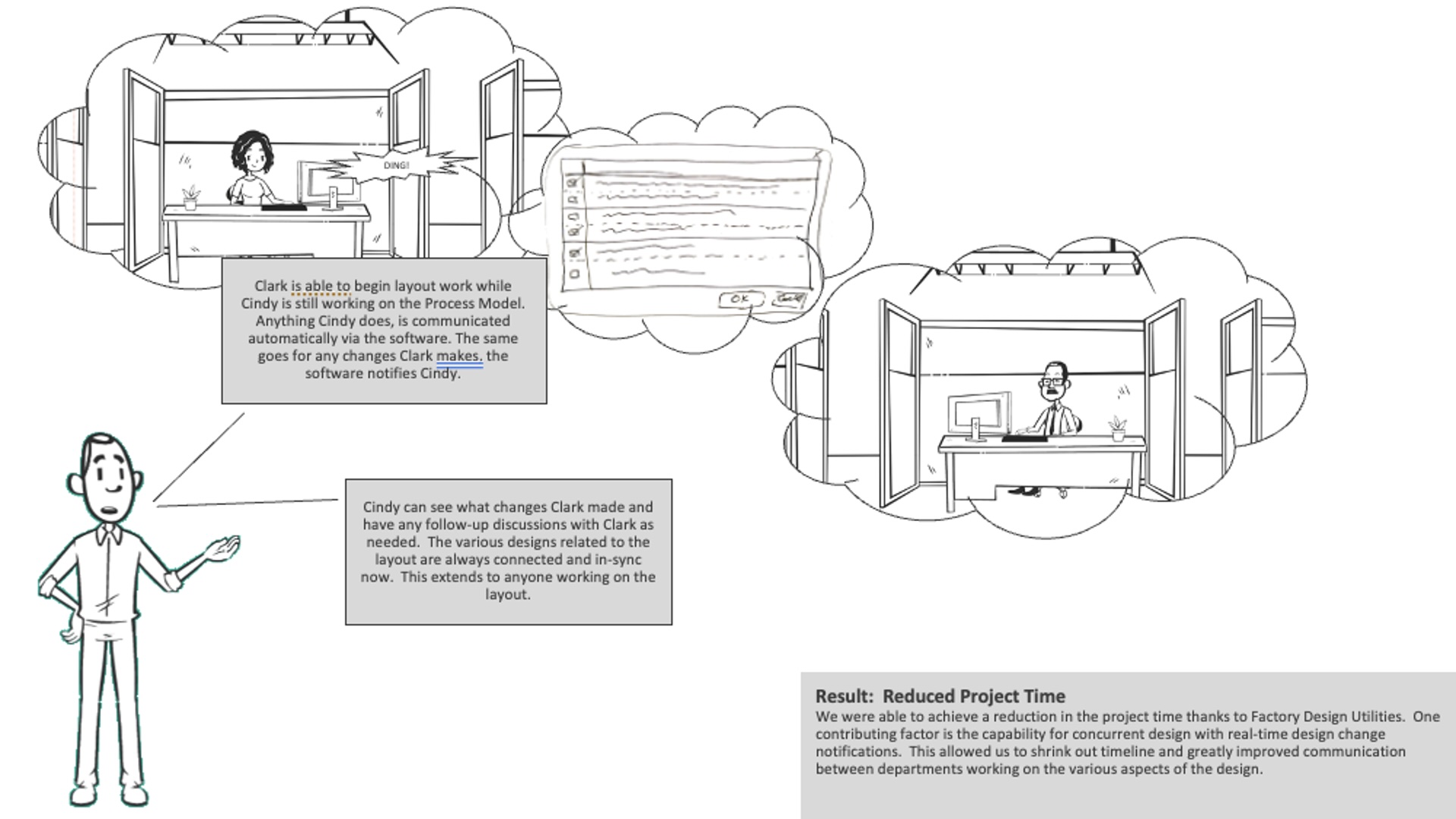

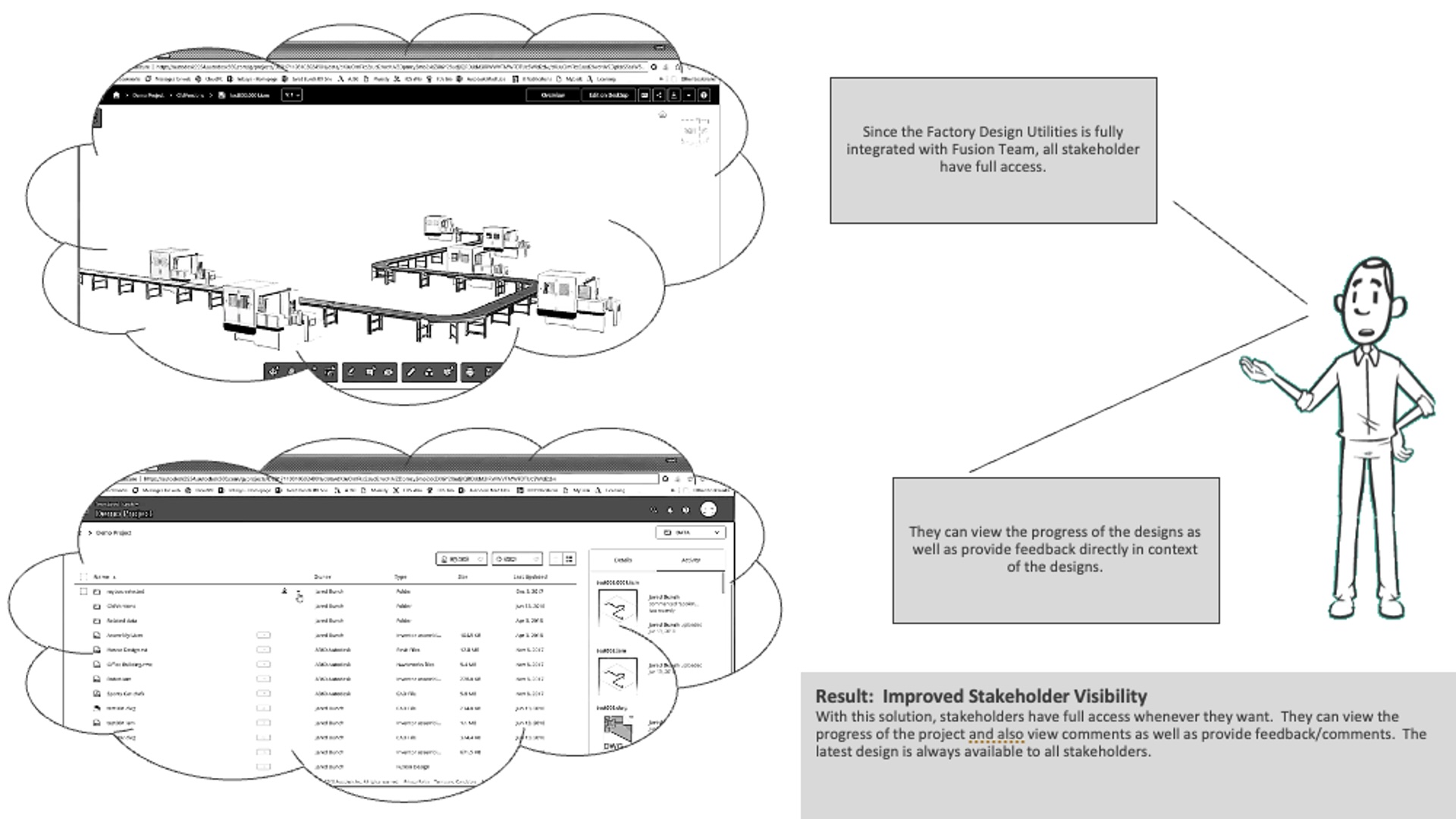

I used storyboards to walk the leadership team through the big picture vision. This was about the story of a transforming the factory design process and the value customers would see from the changes, not just screens.

Digging a bit deeper

We take a closer look at our key areas: Connections, Real Time Design Change Alerts, and Conflict Resolution

Connections

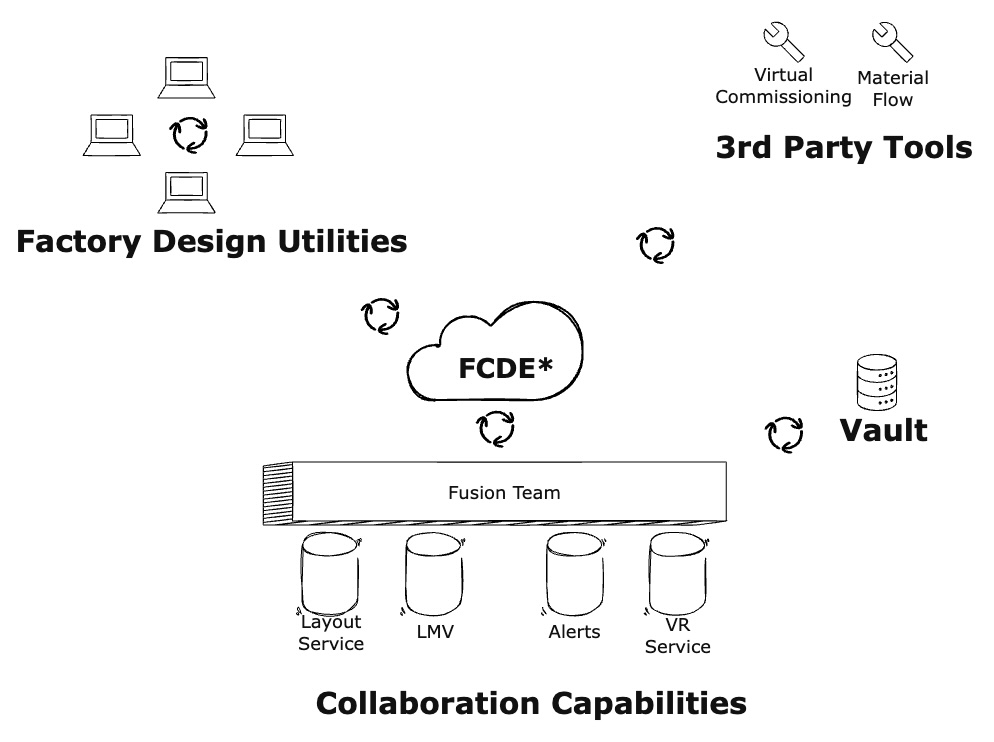

The illustration shows how we might create a central, source of truth, with the FCDE (Factory Common Data Environment). This would provide a single data source that all the various tools could connect, share, and communicate through.

Real Time Design Change Alerts

With the FCDE, connected users will receive live design change alerts. Also, when opening the unreleased designs, they will always be up-to-date.

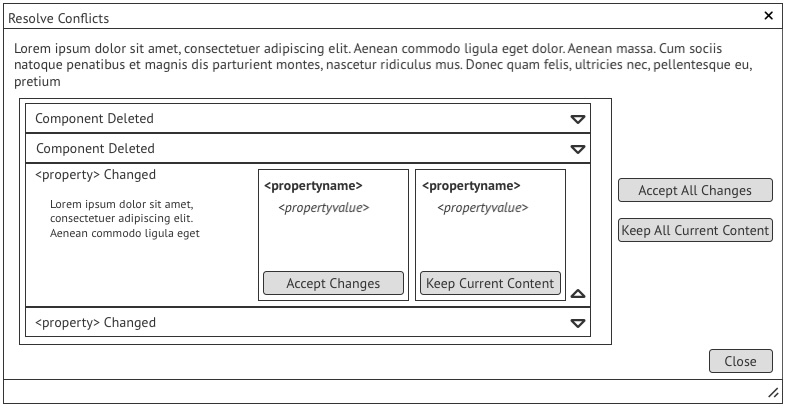

Conflict Resolution

While automatic resolution of conflicts is the goal, it is unrealistic to think it will be achievable 100% of the time. If conflicts cannot be resolved, user interaction will be required to help determine which change to keep.

Stakeholder Alignment

I successfully aligned global stakeholders and a division VP on a unified product strategy.

Foundation for Innovation

My research and vision directly led to the development of the Factory Common Data Environment.

Customer Centric Strategy

I interviewed and surveyed a diverse range of users to ensure the technical vision was grounded in actual customer needs.

Final thoughts

The work and illustrations shared here are a sampling of the broader vision I developed for the Factory Design Utilities product. To build this, I spent months surveying and interviewing existing customers, trial users, and internal experts to make sure our plan was grounded in reality. I then presented these findings to a wide group of leaders, including UX and product leadership, engineering heads, and the division VP.

The value shown in this vision was clear enough that it led to the creation and delivery of the Factory Common Data Environment. This was a massive win and provided the foundation for everything else we planned to build.

After that initial success, a change in leadership and a shift in company priorities moved resources away from this specific product line. While the full vision was not realized, the project remains a great example of how deep research and a clear strategy can align a global team and move a product into a modern, cloud first era.